Are you struggling to create accurate and efficient shop drawings for your construction project? Look no further! In this post, we will guide you through the process of creating professional shop drawings that will streamline the construction process and ensure project success.

Pain Points of Making Shop Drawings

Creating shop drawings can be a daunting task, especially for beginners. The process can be time-consuming and complex, and mistakes can have serious consequences on the project timeline and budget. Many factors must be taken into consideration, such as measurements, materials, and structural requirements. Fortunately, with the right approach, software, and knowledge, anyone can produce top-notch shop drawings.

How to Make Shop Drawings?

The first step in creating shop drawings is to understand the project requirements thoroughly. Review the specifications and drawings provided by the client to ensure complete comprehension of the project scope. Next, take accurate measurements of the area where the components will be installed. Once the measurements are taken, create a 2D or 3D model using computer-aided design (CAD) software.

The CAD model serves as the foundation for the shop drawings. Add annotations, dimensions, and notes to the model to specify details and ensure clarity. Include the necessary views, such as elevation, plan, section, and isometric views. Review the plan with other team members and the client to confirm accuracy and address any concerns. Finally, export the shop drawings in a format that the manufacturer can understand, such as PDF or DWG.

Summary of Main Points

Creating shop drawings requires a thorough understanding of the project scope, accurate measurements, CAD software, and meticulous attention to detail. The process can be simplified by breaking it down into manageable steps and working collaboratively with team members and clients to ensure accuracy and clarity.

Importance of Uniqueness in Shop Drawings

One of the essential aspects of creating shop drawings is ensuring that the components are unique and customized to the project's needs. Stock components may not fit precisely, leading to issues during installation. Creating custom shop drawings is necessary to ensure seamless component integration and efficient construction.

When I was working on a tile installation project, I created shop drawings that were unique to that specific project. I ensured that each tile was cut to precise measurements and aligned correctly with the other components. The unique shop drawings allowed for seamless tile installation, without any delays or errors.

Efficiency in Shop Drawings

Efficiency is crucial when creating shop drawings. Creating unique components can take time, but by using software and collaborating with team members, the process can be streamlined. Utilizing software such as Bluebeam and SketchUp can increase efficiency by automating certain functions, reducing the chances of errors, and speeding up the overall process.

When I was working on a custom cabinet project, I used SketchUp to create 3D models of each cabinet, with accurate measurements and detailed annotations. The software allowed me to visualize the final product and make necessary changes before the manufacturing stage. It also enabled me to communicate the design with team members and clients accurately.

Importance of Collaboration in Shop Drawings

Creating shop drawings requires teamwork and collaboration. Collaboration ensures that the project's requirements are met and shared understanding is achieved. The input of other team members, such as architects, engineers, and manufacturers, can also help improve the quality of the final product and reduce errors.

When I was working on a metalwork project, I collaborated with the manufacturer to ensure that the shop drawings were accurate and met their manufacturing requirements. The collaboration also allowed me to understand their limitations and provided me with an insight into the manufacturing process.

Question and Answer

Q: What software can be used to create shop drawings?

A: There are many CAD software available, such as AutoCAD, SketchUp, Bluebeam, and Revit.

Q: What is the most critical aspect of creating shop drawings?

A: Attention to detail is essential when creating shop drawings to ensure accuracy and clarity.

Q: Why is collaboration important in shop drawings?

A: Collaboration helps ensure that project requirements are met, shared understanding is achieved, and the final product is of high quality.

Q: What are the consequences of incorrect shop drawings?

A: Incorrect shop drawings can lead to project delays, increased costs, and safety issues.

Conclusion

The process of creating shop drawings may seem daunting, but with the right approach and software, anyone can create top-notch components. It is essential to understand the project requirements fully, take accurate measurements, and pay attention to detail. Collaboration with team members and clients can also help improve the quality of the final product. By following these guidelines, you can create efficient and accurate shop drawings that streamline the construction process and ensure project success.

Gallery

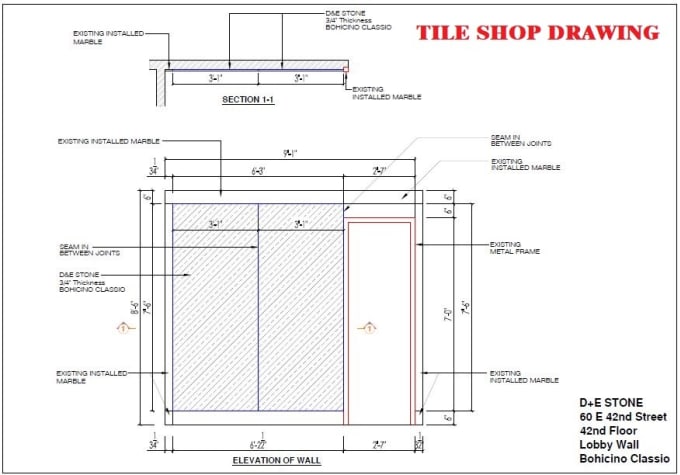

Make Shop Drawings For Tiles By Musadhik | Fiverr

Photo Credit by: bing.com / fiverr

Are Shop Drawings Part Of The Contract Documents - Shop Poin

Photo Credit by: bing.com / superior

Shop Drawings | FB Designs

Photo Credit by: bing.com / shop drawings drawing millwork custom nyc

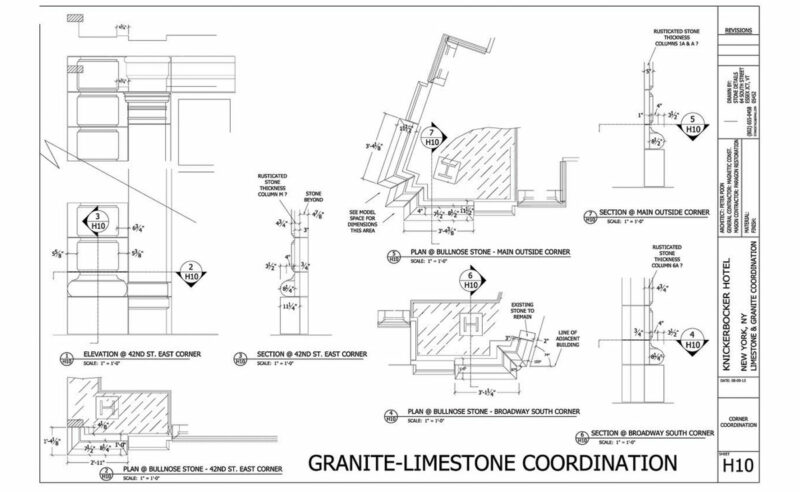

Shop Drawing Specifications – Stone Details

Photo Credit by: bing.com / coordination

Creating Professional Shop Drawings Using SketchUp LayOut – CabWriter

Photo Credit by: bing.com / shop drawings plan layout professional sketchup symbols drawing 2d create floor notes section dimensions creating using