Are you struggling with wiring diagram for air compressor motor? Do you find yourself wasting hours trying to figure out the right connections? Fret not, as we have got you covered. In this post, we will discuss everything you need to know about wiring diagram for air compressor motor, including the pain points, target, and tips for efficient wiring.

Pain Points Related to Wiring Diagram for Air Compressor Motor

Wiring diagram for air compressor motor can be a complicated process, especially for those who are new to it. Some common pain points include incorrect connections, overheating, and incorrect voltage. These problems can lead to frequent breakdowns, resulting in costly repairs and downtime. Additionally, these problems can also pose safety hazards, making it crucial to ensure proper wiring connections.

Target of Wiring Diagram for Air Compressor Motor

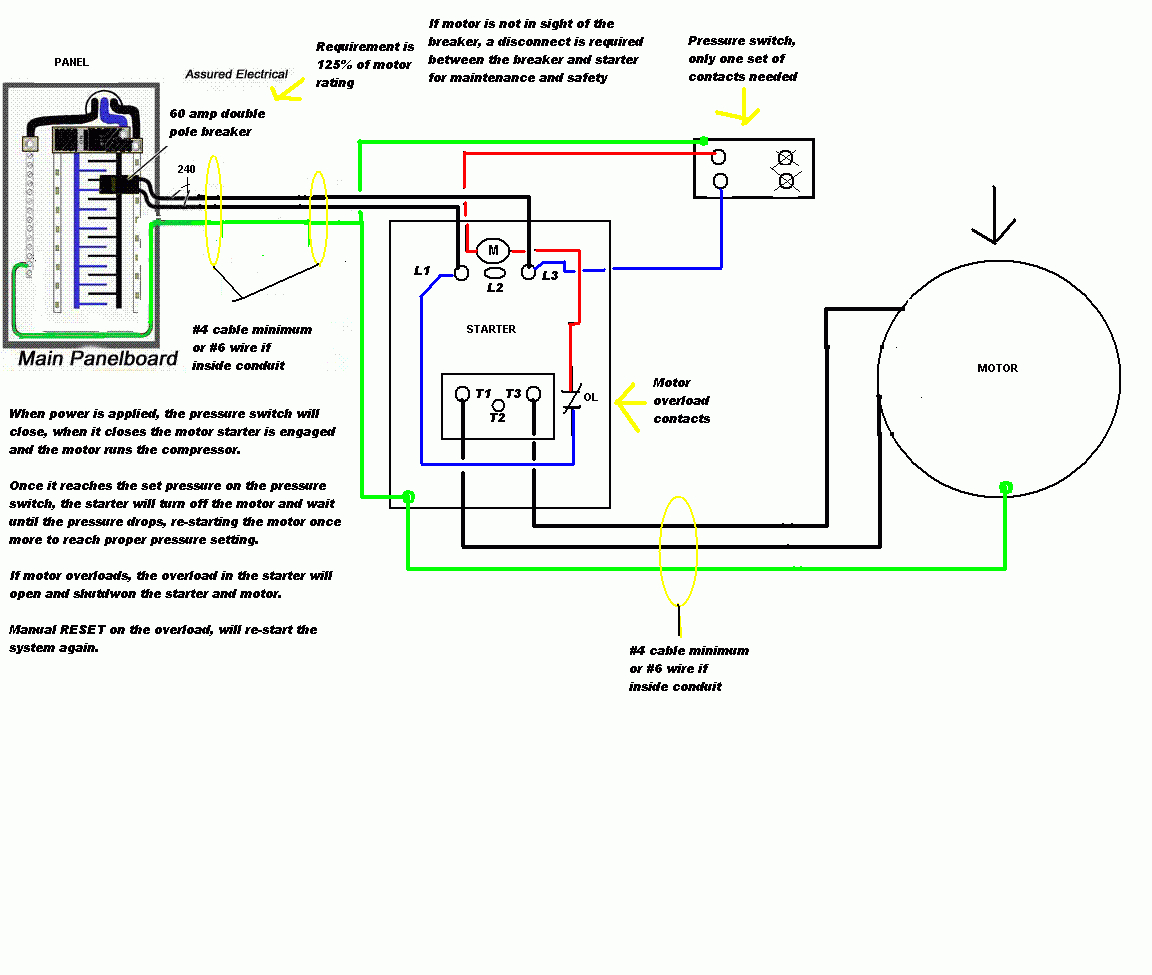

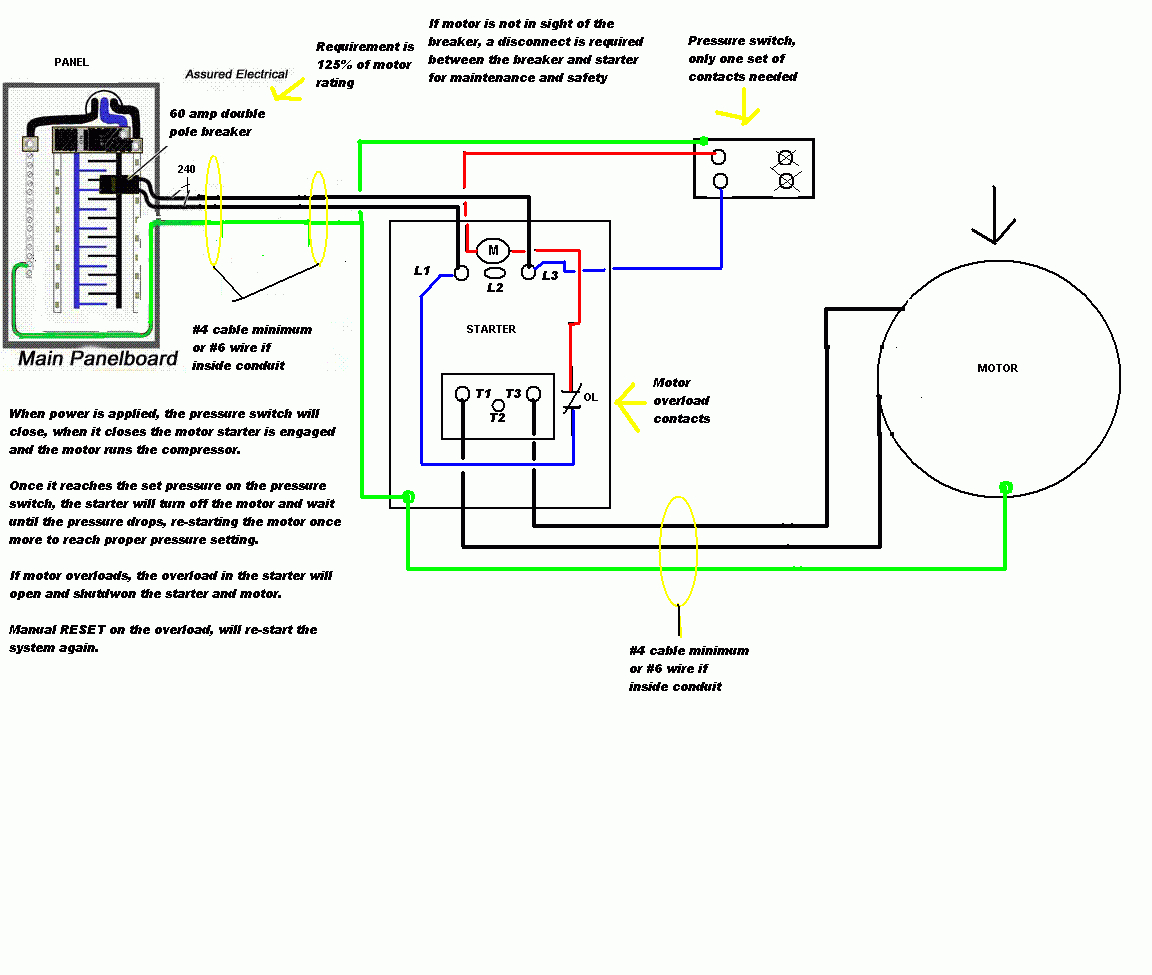

The primary target of wiring diagram for air compressor motor is to provide a clear and concise layout of the wiring connections required for proper operation. This diagram typically includes a wiring schematic that illustrates the circuit path and the correct connections. This information is essential in ensuring the correct voltage, current, and frequency are supplied to the motor.

Summary of Main Points Related to Wiring Diagram for Air Compressor Motor

Proper wiring is crucial for the efficient and safe operation of air compressor motors. Issues such as incorrect connections, overheating, and incorrect voltage can lead to frequent breakdowns and safety hazards. The primary target of wiring diagram for air compressor motor is to provide a clear and concise layout of the wiring connections required for proper operation, including a wiring schematic.

Importance of Wiring Diagram for Air Compressor Motor

Wiring diagram for air compressor motor is essential for maintenance and troubleshooting. Furthermore, having one on hand can also save time and money on repairs as it provides a clear guide on how to connect the various components of an air compressor. Before starting the wiring process, it is crucial to have a solid understanding of the wiring diagram and the specific requirements for the motor in question.

Tips for Efficient Wiring Diagram for Air Compressor Motor

When working with wiring diagram for air compressor motor, it is essential to follow some best practices to ensure efficient and safe wiring. Firstly, always ensure that the power is disconnected before starting the wiring process to prevent electrical shock. It is also important to follow the manufacturer's instructions and label all wires using a wire marker to ensure easy identification. Finally, ensure that the wiring connections are tight to prevent arcing and overheating.

Common Mistakes to Avoid in Wiring Diagram for Air Compressor Motor

There are several common mistakes to avoid when wiring diagram for air compressor motor. Firstly, always ensure the correct voltage and frequency are used to prevent overheating and other complications. Secondly, avoid connecting wires without proper labeling as this can lead to confusion during repair and maintenance. Finally, ensure proper wire size is used for each connection to prevent damage to the motor or other components.

Benefits of Proper Wiring Diagram for Air Compressor Motor

Proper wiring connections can lead to numerous benefits, including efficient operation, reduced risk of breakdowns, and extended lifespan of the motor. Additionally, proper wiring also ensures safety for both the air compressor and the operator.

Question and Answer

- Q: Can wiring diagram for air compressor motor be customized for specific motors?

- A: Yes, most wiring diagrams for air compressor motor can be customized for specific models.

- Q: Can incorrect wiring damage the air compressor motor?

- A: Yes, incorrect wiring can lead to damage to the motor as well as other components.

- Q: How often should wiring connections be checked?

- A: It is recommended to check connections regularly, especially after prolonged use or any maintenance work.

- Q: What should you do if you are not familiar with wiring diagrams?

- A: If you are not familiar with wiring diagrams, it is recommended to seek assistance from a qualified technician or professional.

Conclusion

Wiring diagram for air compressor motor is an essential tool for ensuring the efficient and safe operation of air compressor motors. Proper wiring connections lead to numerous benefits, including extended lifespan, reduced risk of breakdowns, and enhanced safety. By following best practices and avoiding mistakes, you can ensure a smooth and hassle-free wiring process for your air compressor motors.

Gallery

Air Compressor Wiring Diagram 230v 1 Phase | Free Wiring Diagram

Photo Credit by: bing.com / compressor wiring diagram air phase rand ingersoll copeland 230v refrigerator t30 relay ac single pressor whirlpool start motor inspirational beautiful

Copeland Wiring Diagrams - Wiring Data Diagram - Compressor Wiring

Photo Credit by: bing.com / compressor wiring phase diagram single motor capacitor ac copeland electrical 220v data diagrams schematics correct manual books

Wiring Diagram For Electric Motor For Craftsman Air Compressor Model

Photo Credit by: bing.com / craftsman 240v fixya

Air Compressor Wiring Diagram 230V 1 Phase - Cadician's Blog

Photo Credit by: bing.com / wiring compressor

240v Motor Wiring Diagram Single Phase - Free Wiring Diagram

Photo Credit by: bing.com / wiring diagram motor phase single 240v electric marathon ao smith motors